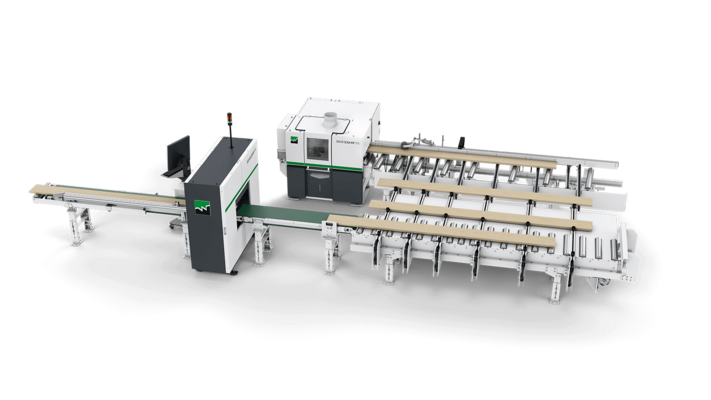

The SYSTEM SCAN RIP 310 combines a scanner, mechanization and a rip saw into one simple, robust, and cost-effective solution. Optimization is based on the shape of the boards and the detection of major visible gross defects, ideal for companies looking to get started with a smart, streamlined setup.

Exclusively constructed for the needs of US enterprises and with fully automated transport!

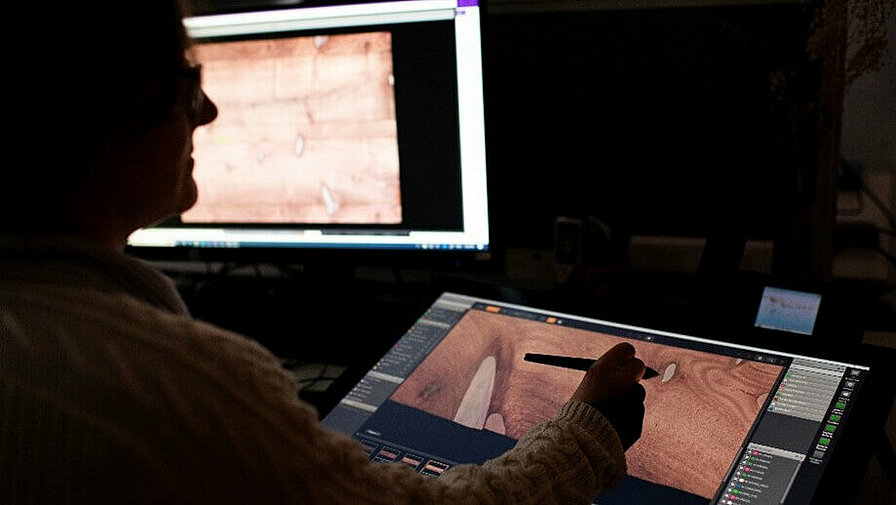

Increase your yield with the AI

The artificial intelligence analyzes the actual shape of each board as well as visible defects such as knots and cracks. This ensures that every piece is individually optimized for maximum value.

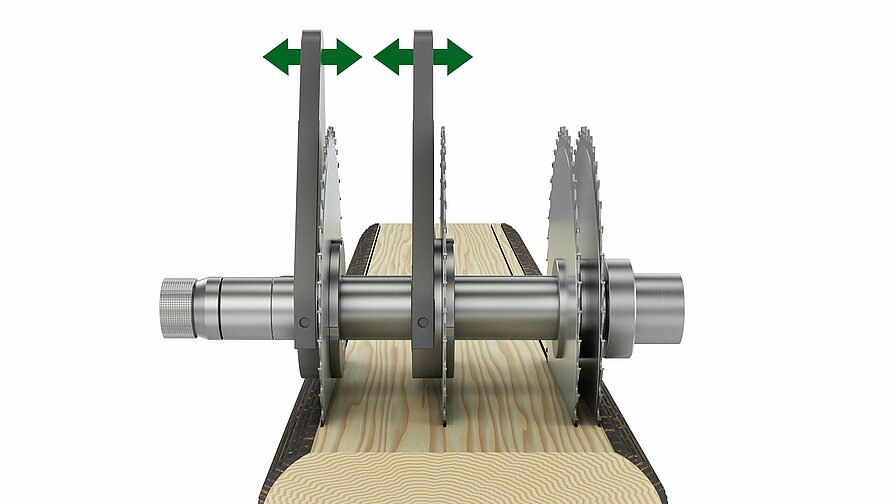

Maximum yield and cutting quality

With dual blade‑adjustment technology and exceptional cut precision, the system boosts recovery on every pre‑edged board.

Ideal for small to medium‑sized operations

A cost‑effective solution offering an outstanding price‑performance ratio and a fast return on investment (ROI).

TECHNICAL DETAILS

- Max Boards / min

- 8 pcs.. (at 50 m/min andaBoard lengthof 3m)

- Boards Length

- min./max. 1000 –5000 mm

- Boards Width

- min./max. 100 –310 mm

- Boards Thickness

- min./max. 20 –100 mm

- Pre edged Material

- x

- Defect detection with AI

- x

- Optimization process with moving blades

- x

- Automated material transport, positioning and feeding

- x

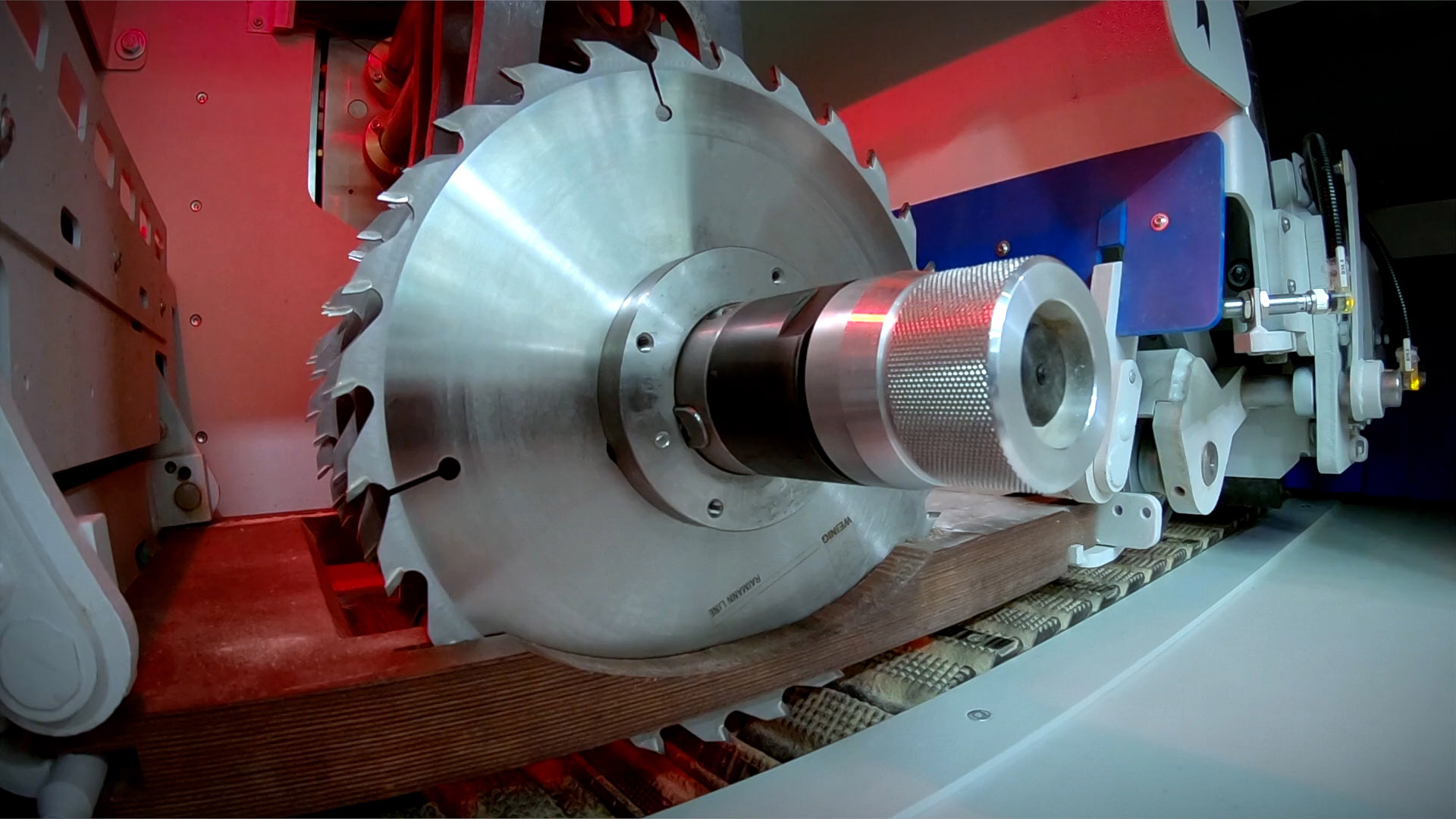

Diamond‑Blade Precision, Redefined

The world’s first of its kind, this breakthrough is made possible by an innovative new blade‑manufacturing process that sets an entirely new standard in precision cutting. Its patented “crown‑tooth” geometry is unique in the industry and delivers exceptional performance you won’t find anywhere else. Even at extremely high feed speeds, the blade produces glue‑ready cut quality, giving manufacturers a decisive edge in efficiency and output.

- Significantly longer tool life (at least 50×)

- Reduced setup time

- Tear‑free edges

- Higher productivity

- Lower noise levels and reduced power consumption

- Performs in both hardwood and softwood, even with knots

OUR FAQ SECTION

Increase your ROI now

Get expert advice and benefit from our unbeatable performance package for your operation.