AT THE SIDE OF WINDOW MANUFACTURERS FOR OVER 45 YEARS

Weinig offers more! From solutions for individual production steps to interlinked and automated systems, Weinig works with its customers to develop the future of window, door and furniture production.

Weinig launches the first special machines for window production as angular systems.

With over 3,500 machines installed, including over 700 CNC machining centers, Weinig is one of the leading manufacturers worldwide.

Weinig window machines are in operation in over 35 countries.

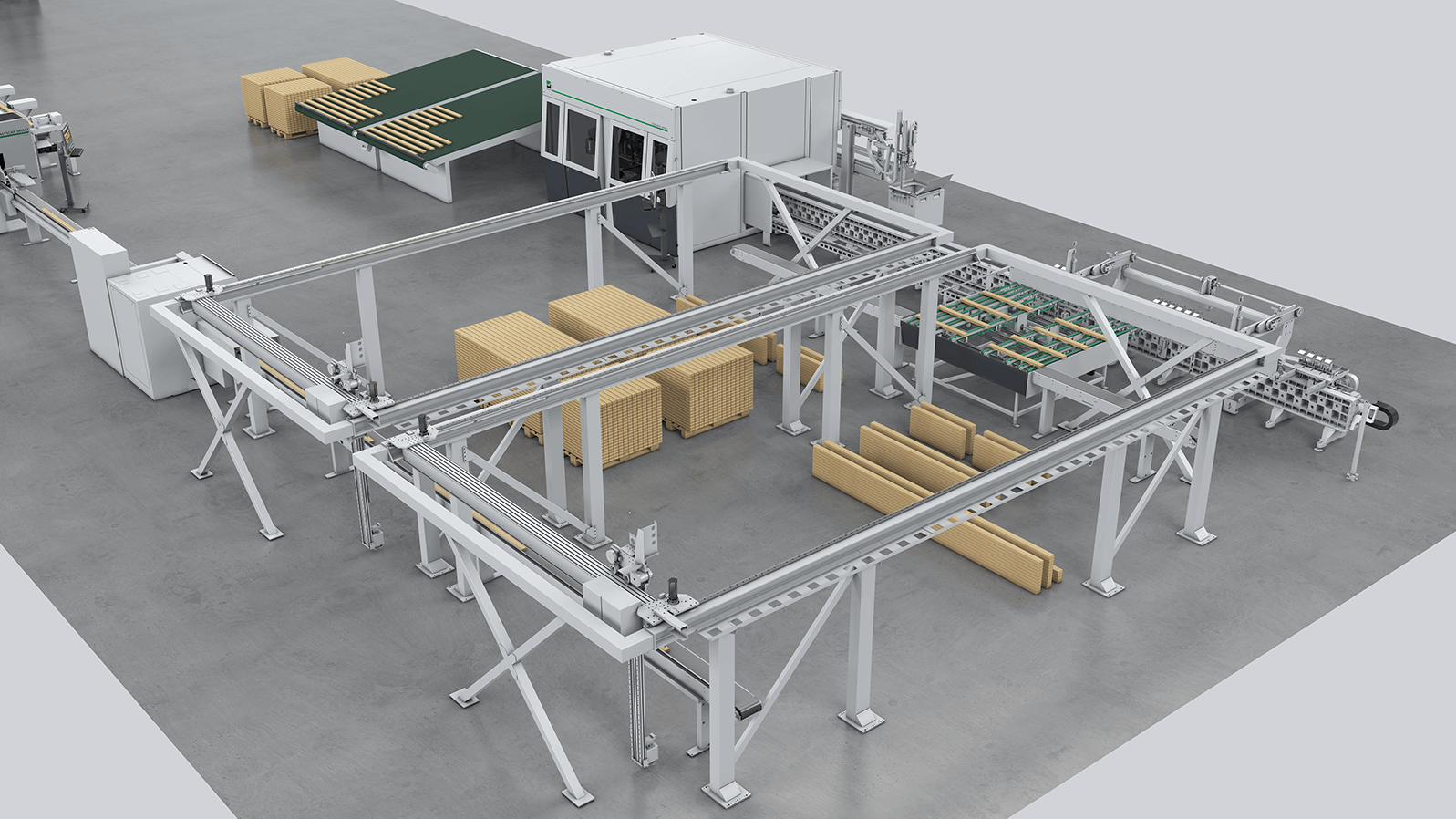

AUTOMATION AND MECHANIZATION SOLUTIONS

Our Weinig System Solution (WSS) team is your point of contact when it comes to planning and successfully implementing your requirements. By incorporating the diverse products of the Weinig Group and integrating existing machines and purchased components, Weinig can realize your production line for a successful future.

- Effective and ergonomic solutions for smaller quantities < 200 parts per shift

- Combination of manual and automated manufacturing solutions for medium quantities according to your needs

- Industrial production lines with up to 2,000 parts per shift and more, which impress with their reliability, efficiency and innovation

WEINIG SUCCESS STORY

Stocker Fensterbau AG, based in central Switzerland, planned a comprehensive modernization of its production facilities in cooperation with WEINIG and implemented it in 2024. Due to a change prior to LIGNA 2025, the products mentioned in the video are now marketed under a different name.

- Cutting: OptiCut S 90 (now: SOLID CUT PF 900)

- Planing: Powermat 700 (now: SOLID PROFILE P 700)

- Mechanization (cross conveyor)

- Sanding: SOLID FINISH sanding machine (belt sanding and/or Rotofinish®)

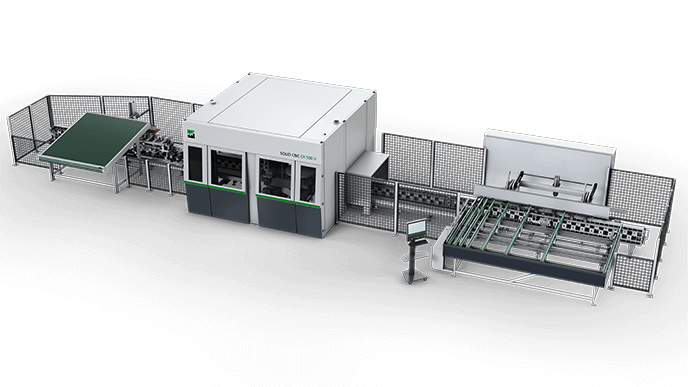

- Profiling: Fully integrated Conturex C326 (now:SOLID CNC CR 700)

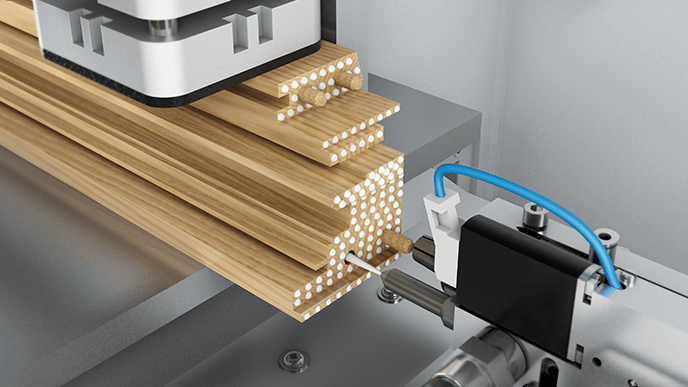

- Dübeln und Verleimen:UniPin 200 (now: SOLID PIN PVAc)

OUR CNC WINDOW MANUFACTURING MACHINES

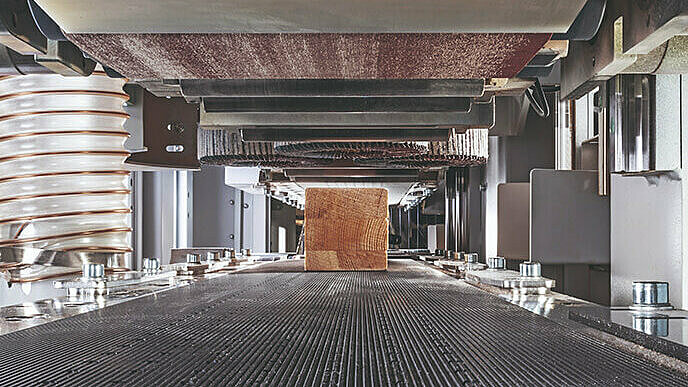

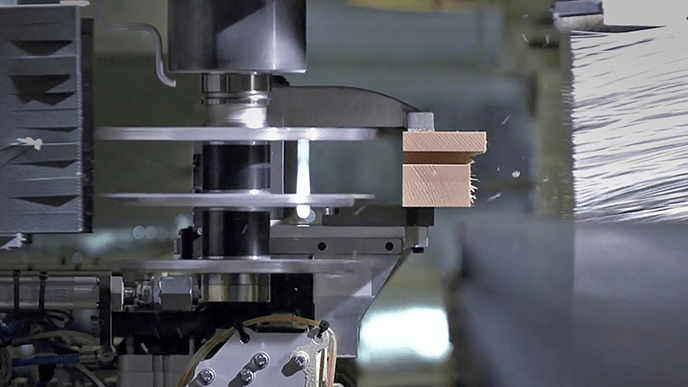

PROFILING, DRILLING, AND ROUTING IN ONE

With the machines in the SOLID CNC CR series, you can manufacture windows in accordance with the applicable standards for your markets. Thanks to WEINIG 3D clamping technology, there are virtually no limits to profile processing. Do your customers want narrow wood faces, historic windows, shutters, modern windows or facade and door elements? WEINIG SOLID CNC CR technology enables you to meet these requirements from a batch size of 1.

Choose your CNC window machine from several Weinig models based on quantity and/or application. This allows you to produce 20 to 85 complete window frames or 160 to 680 parts in an 8-hour shift.* With our SOLID SYSTEM CR production lines, the production volume can also be increased to 1,920 pieces and more per 8-hour shift.**

* Information based on the production of the Weinig sample window

** Information from one of our customer projects

OVERVIEW OF TECHNICAL ADVANTAGES

Workpiece dimensions

From the smallest wooden bar with a clear dimension of only 175 mm (optionally 140 mm) and a width of 20 mm to a large-dimensioned post-and-beam or conservatory element with a length of up to 6000 mm and a width of up to 330 mm (from CR 400 V Standard)

Corner connections

All corner joint variants are available to you, for example slot and tenon, counter profile and dowel, round tenon corner joint or mechanical corner joints. Retrofitting, converting, or adding tools and software data for corner joint variants is also possible at any time.

Material

At WEINIG, we carry out tests with all clampable materials in the specified dimensions. This means that our customers can process not only solid wood, modified woods and wood-based materials but also plastics and composite materials (even aluminum composites).

SEAMLESS DATA INTEGRATION

The networked systems of the future require a consistent software solution from the idea to the finished workpiece. This is the only way to ensure maximum transparency of processes. We provide our customers with various standard interfaces for fast and easy data transfer, for example to WOP, CAD/CAM programs or ERP systems. Over time Weinig has implemented solutions and defined standards with a large number of software companies. The processes of wood optimization, pre-planing, sorting, CNC machining and comprehensive automation from Weinig combine to form a highly effective network—with just one data set for all machines and their peripherals.

Is your partner not listed? No problem, we also integrate new systems (optional).

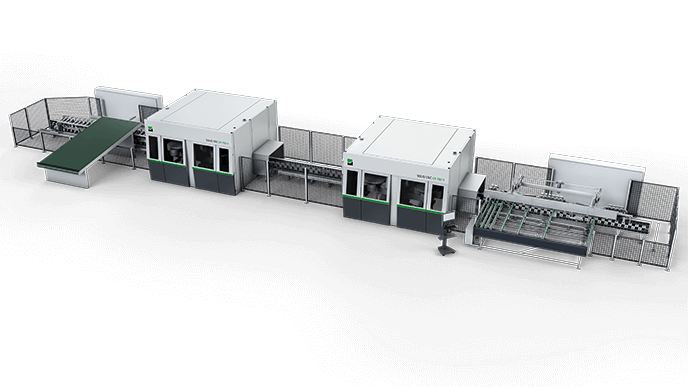

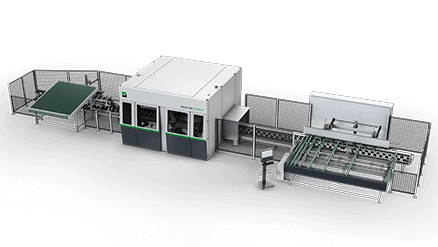

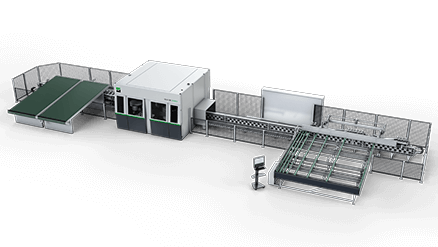

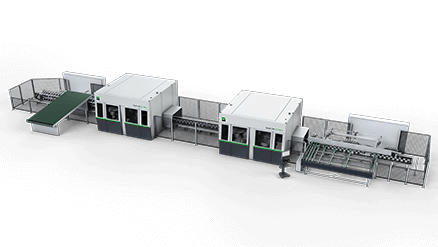

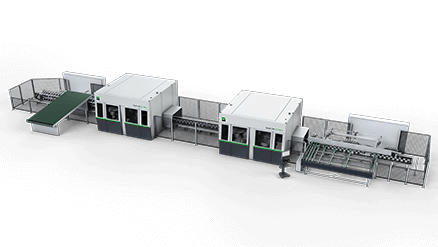

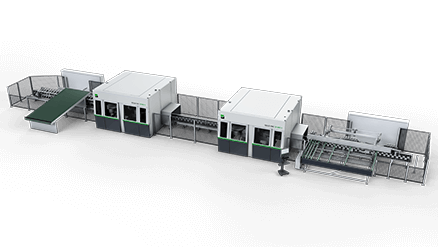

SOLID SYSTEM CR

THE TAILOR-MADE SOLUTION

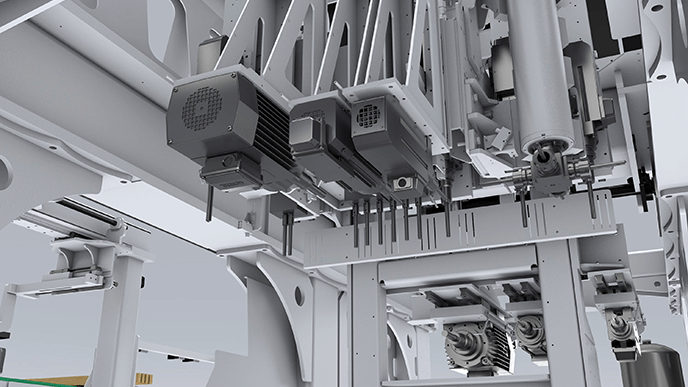

Weinig offers exactly the right solution depending on the required quantity and desired degree of automation. Thanks to the modular design, we can respond to your individual needs.

With SOLID SYSTEM CR, we also offer our flagship technology, which—depending on the component geometry—achieves peak outputs of up to 2,000 parts per shift and more. And all this with consistently high, reproducible quality.

WEINIG SUCCESS STORY

"THE PLUS" is a very special project for our Norwegian customer VESTRE AS. From the outset, the aim of the planning was simply to build the most environmentally friendly furniture factory in the world. We are proud to be part of this project and present here the video from the BBC series "The Spaces That Shape Us." We carried out five production stages (the new names of the machines since LIGNA 2025 are shown in brackets):

- Powermat 700 (now: SOLID PROFILE P 700) for 4-sided planing of workpieces

- Easy Scan Smart (now: SOLID SCAN S), which detects defects on four sides and automatically determines the results for the subsequent saw

- OptiCut 260 (now: SOLID CUT TF 2600), which optimizes and cuts the workpieces based on the scanner results

- Intelligent vacuum/robot buffer system that can temporarily store semi-finished products on the floor

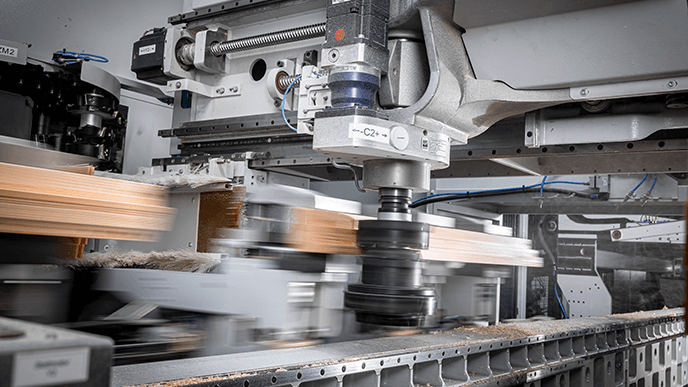

- Conturex Vario L (now: SOLID CNC CR 600 V ) with a 4-part process

As part of the Vestre project, productivity was significantly increased through the use of multi-part mode. Up to four workpieces are processed in succession on one side of the table – a total of up to eight parts can be processed simultaneously in the machine. This optimization significantly reduces non-productive time and enables a significantly higher parts throughput. Depending on the customer's product, a peak output of up to 3.6 parts/minute can be achieved on a CR 600 V.

OUR SERIES IN DETAIL

SOLID CNC GR 200 V

- 1 portal 1 table and 6 single grippers 1 spindle 3D motion technology

SOLID CNC CR 300

- 1 portal

- 2 tables

- Max. 2 spindles

SOLID CNC CR 400 V

- 1 portal

- 2 tables

- Max. 4 spindles

- Multi-part mode

- 3D motion technology

SOLID CNC CR 500 V

- 1 portal

- 4 tables

- Max. 4 spindles

- 3D motion technology

SOLID CNC CR 600 V

- 1 portal

- 4 tables

- Max. 4 spindles

- Multi-part mode

- 3D motion technology

SOLID CNC CR 700

- 2 portals

- 4 tables

- Max. 8 spindles

SOLID CNC CR 700 V

- 2 portals

- 4 tables

- Max. 8 spindles

- 3D motion technology

SOLID CNC CR 800 V

- 2 portals

- 4 tables

- Max. 8 spindles

- 3D motion technology

Get in Touch & Consultation

LLET'S TALK.

Do you have any questions or would you like to request further information? Please contact us using the following form.